Metallurgy

BASIC METALLURGY – METALLURGY

Metallurgy is the science that explores why metals behave the way they do. It explains the properties, behavior, and internal structure of metals. Metallurgy also describes the treatment and processes that allow us to tailor a metal’s properties to a specific application. As a material engineer study of basic metallurgy will help you to develop, design and operate processes that transform raw materials into useful engineering products intended to improve the quality of our lives. The module therefore explains how to extract the metals for industrial practices.

Duration : 1 hours

Validity : 2 Months

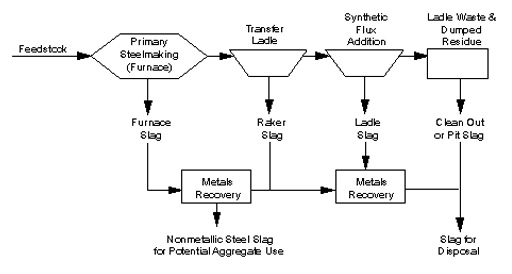

PRIMARY STEEL MAKING – METALLURGY

Steel making is the process for producing steel from iron ore and scrap. In steel making, impurities such as nitrogen, silicon, phosphorus, Sulphur and excess carbon are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, and vanadium are added to produce different grades of steel. Limiting dissolved gases such as nitrogen and oxygen, and entrained impurities (termed “Inclusions”) in the steel is also important to ensure the quality of the products cast from the liquid steel. The module takes us through the best steel making practices in an industry.

Duration : 1 hours

Validity : 2 Months

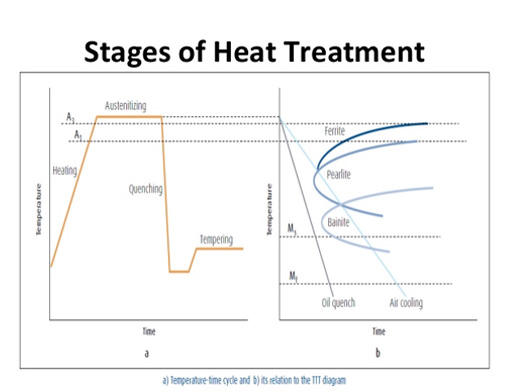

HEAT TREATMENT- MECHANICAL/METALLURGY

Heat Treatment is the heating and cooling of metals to change their physical and mechanical properties without letting it change its shape.

Heat Treatment could be said to be a method for strengthening materials but could also be used to alter some mechanical properties such as improving formability, machining etc. The module has different Heat Treatment process that is required to change the physical and chemical properties of metals.

Duration : 1 hours

Validity : 2 Months

REFRACTORIES AND HEATING – METALLURGY

Refractory is the backbone of Steel Industry. In depth understanding of ‘Refractory application and maintenance’ will enable us to manage operational excellence as per current industrial requirements. The E-learning course on “Refractories and heating” will help acquire knowledge in the following areas. Basics of refractory material Types of refractory Monolithic application Properties and testing of refractories. Application of refractory in steel industry. This module is equally useful for people working in Steel Industry & students of Ceramic & Metallurgical discipline.

Duration : 1.5 hours

Validity : 2 Months

SECONDARY STEEL MAKING – METALLURGY

Steel Making can be divided into three parts. Primary Steel Making, Secondary Steel making and Casting. Secondary Steel making Process is the process where final refining and finishing treatment is done after primary steelmaking to achieve required quality of Steel. With increase of stringent quality requirement of steel, the role of secondary steel making in steel making is getting more important. Keeping in view of the increasing importance of Secondary Steel making in Steel making process, the E-Learning module in Secondary Steel making has been made which help in learning following things:- The definition and importance of Secondary Steel making Process flow of different secondary steel making route Basic principle applied in Secondary Steel making process Detail description, working principle and operation of different Secondary Steel making Process This module is suitable for the people who are working in steel plant and its supply chain, wants to work in steel plants and its supply chain or wants to understand the process of Steel Plant.

Duration : 1.5 hours

Validity : 2 Months